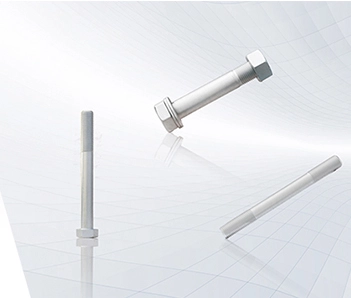

High-strength bolts determine the main connection functions of high-end machinery and equipment, reflect the service life, reliability and economic affordability of machinery and equipment, and are the core of high-end machinery manufacturing.

Fatigue is a failure mode in which one or more bolts crack or break under the repeated action of cyclic stress and strain. Fatigue includes two processes, crack initiation and crack propagation, which occur below the yield strength of the material and fail suddenly without obvious deformation. Therefore, compared with other failure forms, fatigue is one of the most dangerous failure forms. For example, the service environment of wind turbines is complex and harsh, which can withstand both dynamic load impact and corrosion environment. The fatigue fracture of connecting bolts used is up to 85%. The main failure mode of high-strength bolts is fatigue. A large number of fatigue failure analysis results of high-strength bolts show that more than 70% of the fatigue failure results from surface damage, decarburization at the joint of head and rod, obvious small cracks in thread processing or discontinuous cutting tool marks, surface corrosion and uneven quenching structure, because there is high stress concentration. These are related to the manufacturing level of fasteners.

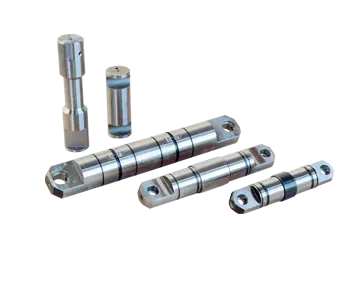

Heat treatment is a process technology that uses heating and cooling methods to control phase transformation, microstructure, residual stress field, and endow material with ultimate performance and high strength bolt with ultimate service performance. It is not only a highly theoretical science, but also a kind of practical technology. It is very practical to say that the advanced heat treatment process is constantly changing with materials and high-strength bolts, and is constantly innovative, developing and improving. High-strength bolts are generally made of high-strength low-alloy steel. It can be seen that no material can leave heat treatment, and no high-strength bolt does not rely on heat treatment. It is necessary to point out that heat treatment is one of the special technologies that endow material with ultimate properties.

Heat treatment technology is an important part of advanced manufacturing technology and plays a very important role in the development of high-strength bolts and high-end mechanical equipment. As we all know, no; Chemical composition does not become material, no; Heat treatment also does not become a material. However, it is often recognized in the traditional fastener manufacturing habits; The importance of chemical composition, but the important role and position of heat treatment are not recognized. The heat treatment process will bring different effects according to the length of time and temperature. Different heat treatment will bring different performance improvements to fasteners.