Tempering Process

Tempering is a heat treatment process that reheats the quenched workpiece to an appropriate temperature below the lower critical temperature, holds it for a period of time, and then cools it to room temperature in air or in a medium such as water or oil.

The purposes of tempering

(1) To eliminate residual stresses generated during quenching, prevent deformation and cracking;

(2) To adjust the hardness, strength, plasticity, and toughness of the workpiece to meet the required performance;

(3) To stabilize the structure and size, and ensure accuracy;

(4) To improve and enhance processing performance.

Classification of Tempering

Low-temperature tempering

Refers to tempering at a temperature of 150~250℃.

Purpose: To maintain high hardness and wear resistance of quenched workpieces, reduce quenching residual stress and brittleness.

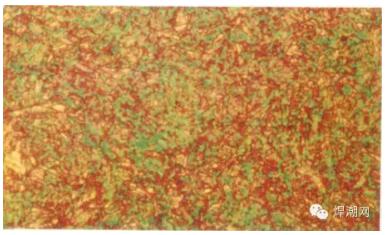

After tempering, tempered martensite is obtained, which refers to the structure formed during low-temperature tempering of martensite.

(Needle-shaped martensite)

Application range: cutting tools, measuring tools, molds, rolling bearings, carburized and surface hardened parts, etc.

Medium-temperature tempering

Refers to tempering at a temperature between 350 and 500℃.

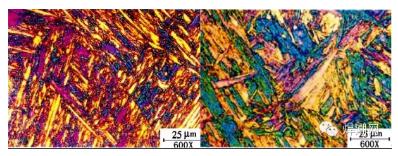

Purpose: To obtain higher elasticity and yield point, as well as proper toughness. After tempering, tempered bainite is obtained, which refers to the complex structure in which extremely fine spherical carbides (or carburized structures) are distributed in the ferrite matrix formed during tempering of martensite.

(Bainite)

Application range: springs, forging dies, impact tools, etc.

High-temperature tempering

Refers to tempering at a temperature above 500℃.

Purpose: To obtain comprehensive mechanical properties with good strength, plasticity, and toughness.

After tempering, tempered sorbite is obtained, which refers to the complex structure in which fine spherical carbides (including carburized structures) are distributed in the ferrite matrix formed during tempering of martensite.

(Sorbite)

Application range: widely used in various important structural components, such as connecting rods, bolts, gears, and shafts, etc.