Our products and services are enjoyed by many famous partners including GE, Siemens Energy, Nordex, Enercon, Goldwind, Envision Energy, Daimler, Caterpillar, Wabtec, MAN Energy Solutions, Wartsila, HHl, Weichai, Yanmar, etc.

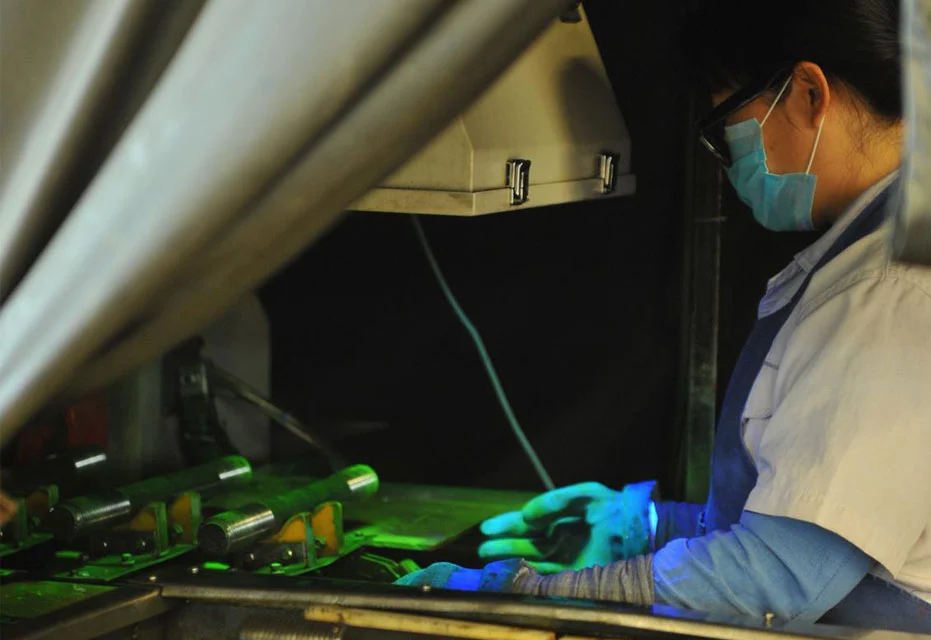

With state-of-the-art manufacturing equipment and the most advanced testing labs. JNZC has been certified with AS 9100D, ISO 9001:2015, IATF16949:2016, IS0 14001, IS0 45001, Dast & CPR, ISO/IEC 17025, TPG (HT, MPI), NADCAP HT & NDT, etc. Our fastener products & machined parts have been awarded certificates issued by classification societies like CCS, DNV·GL, BV, ABS, LR & NK, etc.

Jinan Zhongchuan Equipment Co., Ltd. is always in the light of the principle of trustworthiness, and practical style, with an ingenious and dedicated spirit, to be the most trustworthy industrial fastener supplier of components and services, to protect the world's industrial safety!

中文

中文 English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe ไทย

ไทย