With the widespread application of port tower cranes in the logistics industry, the reliability of their connection systems has become a critical factor in ensuring operational efficiency and safety. This article provides an in-depth analysis of tower crane bolts from several perspectives—including load capacity and preload, strength and stiffness, fatigue life and reliability, as well as vibration and loosening behavior—to support the design and maintenance of port tower cranes.

Load Capacity and Preload of Tower Crane Bolts

Key Factors Affecting Bolt Load Capacity

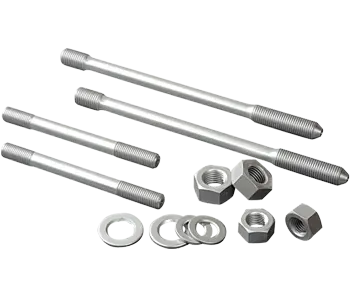

The safe operation of port tower cranes relies heavily on the load-bearing capacity of the bolts in their connection systems. To evaluate the strength of tower crane bolts under various loads, a comprehensive analysis is conducted based on material properties, design codes, and safety margins. The load capacity of a bolt (Pb) is calculated using the formula: Pb = k × As × fy / γm, where k is a coefficient related to the connection type, As is the cross-sectional area of the bolt, fy is the yield strength of the material, and γm is the safety factor.

Importance of Bolt Preload

Preload, the initial tension applied during bolt installation, is critical to the performance of the connection. Proper preload settings must take into account bolt physical properties, dimensions, tightening torque, and frictional characteristics of the contact surfaces. Preload (Fp) is calculated as: Fp = Pb × γb, where γb is the preload coefficient, typically set at 0.7. This ensures that even under extreme conditions, the bolt remains effective, enhancing the stability and safety of the connection.

Strength and Stiffness of Tower Crane Bolts

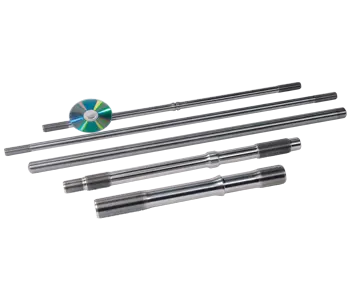

In the assembly and fastening of port tower cranes, bolts play a vital role. To ensure they can safely transmit and withstand the enormous loads and stresses applied by the crane, bolts must meet high standards for tensile strength, shear strength, and fatigue resistance. Table 1 provides examples of physical and mechanical properties for bolts made from different materials.

Table 1: Example of Physical and Mechanical Properties of Bolt Materials

| Bolt Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 45# Steel | 600–800 | 355 | 16–25 |

| 40Cr Steel | 1000–1200 | 800 | 10–20 |

| 35CrMo Steel | 1100–1300 | 930 | 12–18 |

One of the key performance indicators of heavy-duty port cranes is the stiffness of the bolts. Excessive deformation in tower crane bolt connections must be avoided. Therefore, the overall stiffness of the connection system should be optimized to maintain adequate rigidity during operation, preventing any adverse impact on lifting accuracy and structural safety.

Fatigue Life and Reliability of Tower Crane Bolts

Factors Influencing Fatigue Life

The effectiveness of a bolt under repeated stress depends on its fatigue life—i.e., the number of load cycles it can withstand without failure. Fatigue life is influenced by material composition, stress amplitude, and load frequency. When selecting bolts, it is essential to consider their material grade and predict service life through appropriate analysis.

The Necessity of Reliability Analysis

Bolt reliability is affected by various factors such as material type, operating environment, and service conditions. A thorough reliability analysis should evaluate load magnitude, stress distribution, material behavior, preload level, operating temperature, corrosion exposure, and vibration effects. This allows for the estimation of reliability metrics and failure probability, guiding preventive measures and ensuring that bolts meet the design reliability requirements.

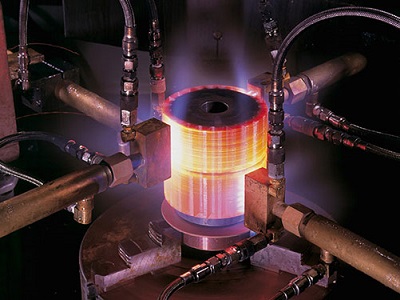

Vibration and Loosening Analysis of Tower Crane Bolts

When analyzing bolt performance under vibration and loosening conditions, it is necessary to examine dynamic loads experienced in complex working environments. These loads can induce fatigue or damage, compromising the safety and stability of the equipment. Finite element modeling and simulation are crucial for accurately predicting stress concentrations and deformation in bolts, thereby estimating fatigue life. A detailed understanding of these factors enables the selection of appropriate bolt specifications and installation methods, enhancing the overall stability of tower crane bolts and ensuring safe and smooth crane operation.

中文

中文 English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe ไทย

ไทย