Factors Leading to Hydrogen Embrittlement

Factors that generate hydrogenThere are various factors that generate hydrogen. In most cases of hydrogen embrittlement failure in fasteners, the highest number of factors come from the pickling and s...

Factors Leading to Hydrogen Embrittlement

Factors that generate hydrogenThere are various factors that generate hydrogen. In most cases of hydrogen embrittlement failure in fasteners, the highest number of factors come from the pickling and s...

What Are the Fatigue Failure Modes of Bolted Connections?

Bolt Assembly Torsion FractureThe characteristic of torsion fracture is obvious necking elongation at the fracture location. The common causes of torsion fracture are mainly due to the small coefficie...

What Are the Fatigue Failure Modes of Bolted Connections?

Bolt Assembly Torsion FractureThe characteristic of torsion fracture is obvious necking elongation at the fracture location. The common causes of torsion fracture are mainly due to the small coefficie...

Classification of Anchor Bolts

Anchor bolts, as an indispensable part of construction and engineering structures, play a crucial role in ensuring the safety and stability of projects. In this article, we will delve into the two mai...

Classification of Anchor Bolts

Anchor bolts, as an indispensable part of construction and engineering structures, play a crucial role in ensuring the safety and stability of projects. In this article, we will delve into the two mai...

The Tightening Torque Standard of High Quality Bolts, The Selection of Pre-Tightening Force and the Checking of Bolt Strength

Standard Tightening Torque for High-Quality BoltsTightening torque and breaking torque are two distinct concepts. Tightening torque refers to the recommended value for screwing the bolt into the workp...

The Tightening Torque Standard of High Quality Bolts, The Selection of Pre-Tightening Force and the Checking of Bolt Strength

Standard Tightening Torque for High-Quality BoltsTightening torque and breaking torque are two distinct concepts. Tightening torque refers to the recommended value for screwing the bolt into the workp...

Heat Dip Galvanizing for Bolt Fasteners Surface Treatment

Bolts play a crucial role as fasteners in various engineering applications, and their surface treatment directly affects their corrosion resistance and overall performance. Among them, hot-dip galvani...

Heat Dip Galvanizing for Bolt Fasteners Surface Treatment

Bolts play a crucial role as fasteners in various engineering applications, and their surface treatment directly affects their corrosion resistance and overall performance. Among them, hot-dip galvani...

What Type of Bolts are Used in Tower Cranes?

In the field of industrial precision machining parts and high-strength special fasteners, bolts play a crucial role in tower cranes. These bolts not only need to withstand high strength and heavy load...

What Type of Bolts are Used in Tower Cranes?

In the field of industrial precision machining parts and high-strength special fasteners, bolts play a crucial role in tower cranes. These bolts not only need to withstand high strength and heavy load...

Structural Design of Fastener Bolt Anti-Rotation Mechanism

In vehicle assembly, the connection commonly uses a fastener bolt and metal nut pairing. During assembly, whether tightening the fastener bolt or the metal nut, a rotation phenomenon can occur. This i...

Structural Design of Fastener Bolt Anti-Rotation Mechanism

In vehicle assembly, the connection commonly uses a fastener bolt and metal nut pairing. During assembly, whether tightening the fastener bolt or the metal nut, a rotation phenomenon can occur. This i...

Tightening Torque for Locking Nuts: Should Locking Torque Be Included?

Locking nuts play a critical role in various industrial applications, particularly in fields such as clean energy, diesel engines, rail locomotives, and steam turbines. Among the considerations surrou...

Tightening Torque for Locking Nuts: Should Locking Torque Be Included?

Locking nuts play a critical role in various industrial applications, particularly in fields such as clean energy, diesel engines, rail locomotives, and steam turbines. Among the considerations surrou...

Factors Leading to Thread Stripping in Threaded Screw

In fastener design, the most common failure mode is bolt fracture, and both a bolt and a nut must be designed to prevent thread stripping. For this reason, when a bolt is paired with a nut, the load-b...

Factors Leading to Thread Stripping in Threaded Screw

In fastener design, the most common failure mode is bolt fracture, and both a bolt and a nut must be designed to prevent thread stripping. For this reason, when a bolt is paired with a nut, the load-b...

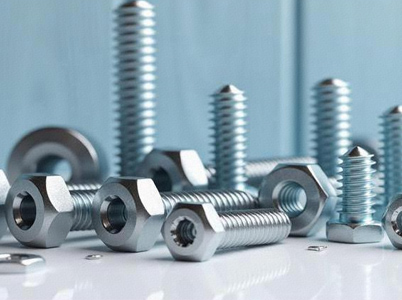

Fastener Bolt: Types of Surface Treatment Processes

Atmospheric corrosion is one of the main types of corrosion damage to a fastener bolt, with the primary corrosion products being iron hydroxides, oxides, and other minor iron compounds. Common surface...

Fastener Bolt: Types of Surface Treatment Processes

Atmospheric corrosion is one of the main types of corrosion damage to a fastener bolt, with the primary corrosion products being iron hydroxides, oxides, and other minor iron compounds. Common surface...

Analysis of Hexagon Shaped Bolt Backing Out Issues

When it comes to the failure of hexagon shaped bolt, common failure modes can be broadly classified into three categories: bolt fracture, bolt loosening, and bolt backing out. Today, we will primarily...

Analysis of Hexagon Shaped Bolt Backing Out Issues

When it comes to the failure of hexagon shaped bolt, common failure modes can be broadly classified into three categories: bolt fracture, bolt loosening, and bolt backing out. Today, we will primarily...

A Guide to Understanding the Double End Stud

What is a Double End Stud?In industrial equipment assembly and connection, a stud plays a crucial role as an essential fastening component. A double end stud is a uniquely designed stud, characterized...

A Guide to Understanding the Double End Stud

What is a Double End Stud?In industrial equipment assembly and connection, a stud plays a crucial role as an essential fastening component. A double end stud is a uniquely designed stud, characterized...

High Strength Bolt: Large Hexagonal Head vs. Shear-off Type

Differences in Appearance Design: The Aesthetics of High Strength BoltAs a key component in structural connections, the design of a high strength bolt plays a significant role in the aesthetic appeal ...

High Strength Bolt: Large Hexagonal Head vs. Shear-off Type

Differences in Appearance Design: The Aesthetics of High Strength BoltAs a key component in structural connections, the design of a high strength bolt plays a significant role in the aesthetic appeal ...

Can a Spring Washer Really Prevent Loosening?

Anti-Loosening Principle of a Spring WasherThe anti-loosening effect of a spring washer comes from its ability to exert a continuous elastic force after being compressed flat. This elastic force maint...

Can a Spring Washer Really Prevent Loosening?

Anti-Loosening Principle of a Spring WasherThe anti-loosening effect of a spring washer comes from its ability to exert a continuous elastic force after being compressed flat. This elastic force maint...

How to Inspect a Threaded Screw

Threads are widely used in industrial fastening connections, and in military products and models, over 80% of structural connections are made using threads. Whether a thread is qualified directly impa...

How to Inspect a Threaded Screw

Threads are widely used in industrial fastening connections, and in military products and models, over 80% of structural connections are made using threads. Whether a thread is qualified directly impa...

中文

中文 English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe ไทย

ไทย